1.Insufficient or deterioration of hydraulic oil: no maintenance for a long time may lead to insufficient or deterioration of hydraulic oil, affecting all the actions of the excavator and making it become slow and weak.

The solution is to check the hydraulic oil volume and replace the new hydraulic if necessary.

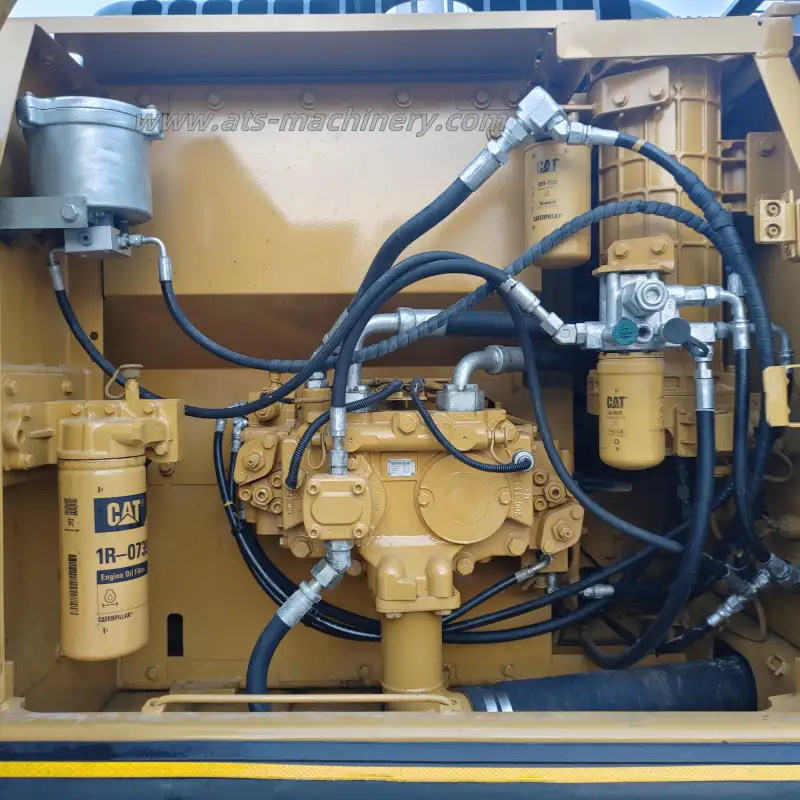

2. Pilot pressure is too low: if the pilot pump is damaged or the pilot filter element is blocked, it will lead to insufficient pilot pressure, which will affect the handle or foot valve control oil circuit can not be fully opened, resulting in all the weak and slow movements.

The solution is to check and repair or replace the pilot pump and filter element.

3.Wear of the main overflow valve: the main overflow valve is the main overflow pressure of the whole car. Once the wear or card is issued, all actions will be affected.

The solution is to check and replace the main overflow valve.

4.hydraulic pump plunger wear: not only will lead to the slow movement of the whole machine , but also may cause high temperature of hydraulic oil and other conditions.

The solution is to check the hydraulic pump plunger and replace it if necessary.

5.Heat dissipation system problems: the reasons for the high temperature may include the poor design or manufacturing of the heat dissipation system, resulting in delayed heat dissipation.

The solution is to regularly check and maintain the heat dissipation system to ensure its normal operation.

6.Oil blockage: if there are more dirt and impurities in the oil system, it will lead to oil blockage, and the oil flow is not smooth, which is affecting the lubrication. The solution is to replace the lubricating oil and filter element in the machine regularly to ensure the smooth oil circuit.

7.Oil product is not suitable: different types of excavators need to use different specifications and types of lubricating oil. The use of inappropriate oil products will affect the normal operation of the lubrication system, resulting in a high oil temperature.

The solution is to select the suitable lubricating oil to ensure that it matches the machine.

8.Bad working environment: the working environment, such as high temperature, dust, more mud, and so on, will lead to the failure of the lubrication and heat dissipation system of the machine, and the phenomenon of high oil temperature occurs.

The solution is to have suitable cooling systems, such as fans and coolers, and equipment such as opening air conditioning to reduce the temperature in the cabin. 9. Internal leakage of hydraulic pump: the internal accessories of hydraulic pump such as cylinder block, plunger, flow distribution plate, swing and other excessive wear, resulting in a large number of internal leakage, resulting in insufficient flow and slow speed.

The solution is to remove the hydraulic pump for data detection, replace the parts that cannot be used, and repair the parts that can be used.

9.Multi-channel distribution valve problem: the setting pressure of the safety valve on the multi-channel distribution valve is insufficient or the gap between the valve stem and the valve hole is too large due to wear, resulting in insufficient flow rate and slow speed.

10.The solution is to remove the multiplex distribution valve for debugging, reset the pressure of all safety valves, and eliminate the gap between the valve stem and the valve hole.